Diesel grout mixer price

Diesel grout mixer manufacturers to win in the future market competition, they must be precise grasp of the future grouting market to produce a grouting machine to meet the needs of the grouting market.

Contact Us

Get Price

Share:

Content 2021-07-02

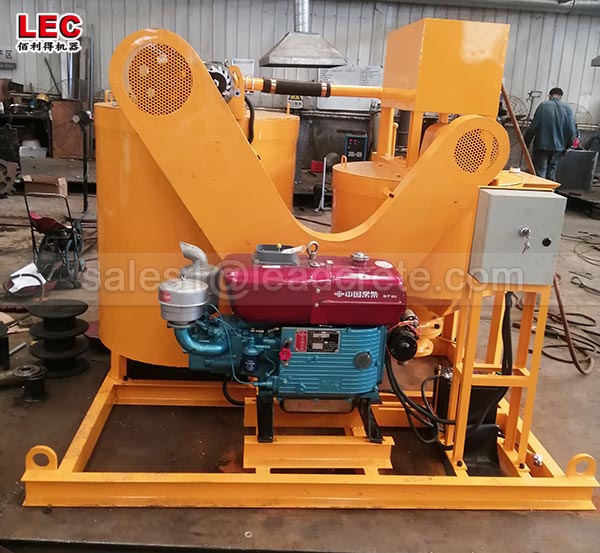

Leadcrete diesel grout mixer for sale with factory price.

Leadcrete diesel grout mixer for sale is a skid mounted system. Leadcrete diesel grout mixer for sale is equipped with a high speed centrifugal impeller pump that disperses the cement material down to its smallest size to achieve complete particle wetting (or wetness) and a powered bridge breaker to precondition material before entering the colloidal mixing pump, the colloidal mixer design very compact, all components are easily accessible for operating, cleaning and maintenance. So one worker could operate the colloidal grout mixer easily. Very save labor cost.

in order to offer one suitable colloidal grout mixer with factory price,

1.What or where will you use Leadcrete diesel grout mixer for? Whether need anti-explosion cement grout mixer? And what’s the voltage?

2.Whether you have one agitator to stock have finished mix cement slurry to avoid sediment, if no, we could offer the agitator for you.

3.Regards the agitator, would you need it with the mixer in one plant or need them separately?

4.Whether you need water tank to add water to the mixer tank?

Any question or demands, please tell us without any hesitation, because we also have our own technical department, it is no problem for us to customized suitable one for you. Call or email to us for one suitable type factory price diesel grout mixer price for grouting works.

Inquiry

More Grout Mixer