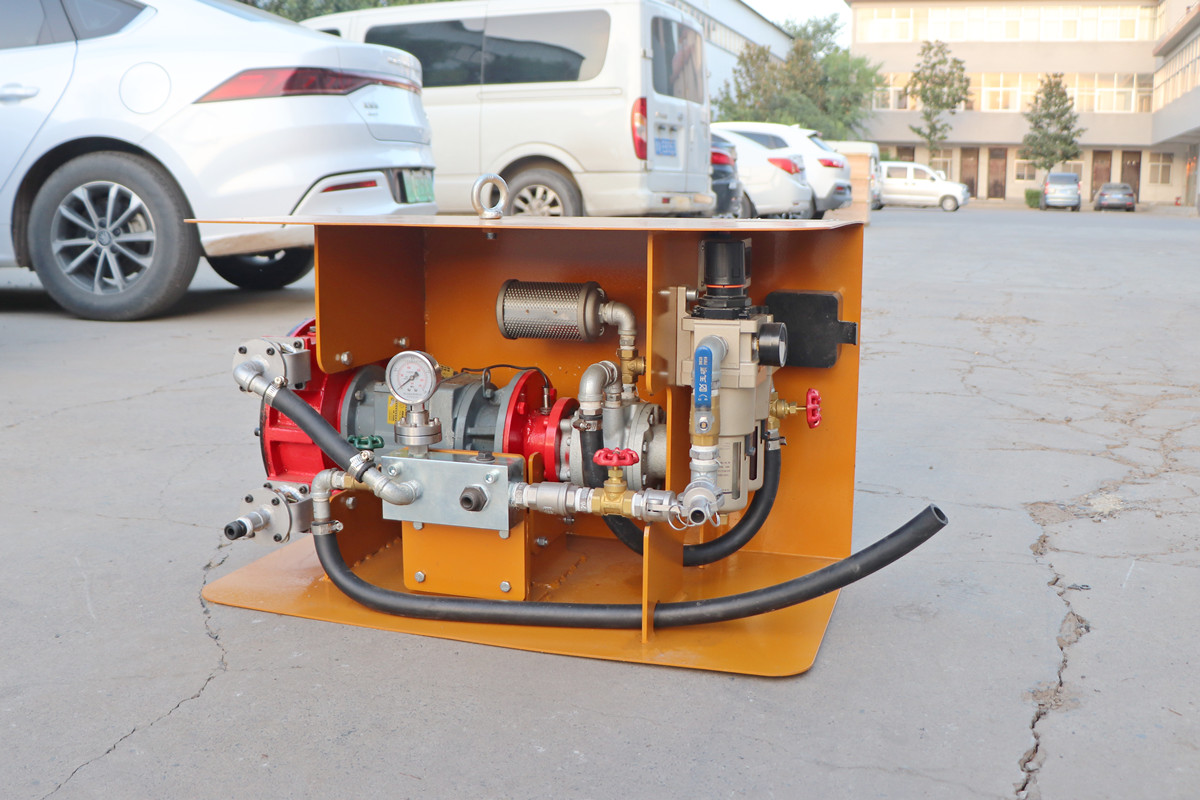

cost saving shotcrete machine with compact structure

The cost saving shotcrete machine with compact structure is applied in many concrete construction applications, like concrete / bridge repair, mining, pool construction, tunneling, Soil Stabilization etc. Customers could choose suitable concrete gunite machine according to different project demands, like required output capacity, max. aggregate size, electric power supply condition etc.

The cost saving shotcrete machine with compact structure is also known as gunite machine, dry materials are fed into hopper, and then material is gravity-fed from hopper to empty pockets of the rotor body. The rotor body isl driven by a motor and gearbox, rotates. The material-filled pocket is positioned under a compressed-air chamber.

Addition of compressed air lifts the material out of the pocket and into the material outlet. Dry material is conveyed in suspension through the conveying hose to the gunite nozzle where water is added and mixed evenly with the dry material.