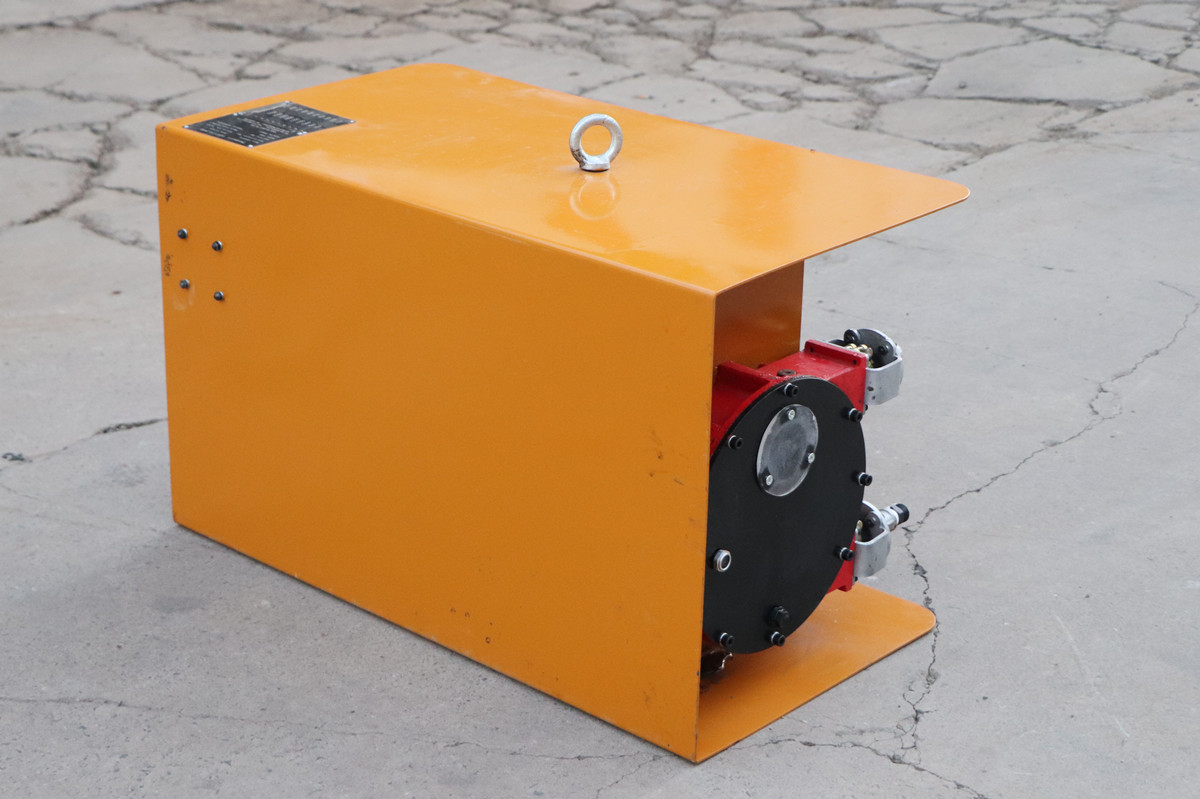

Concrete spraying machine with precise dosing system

Concrete spraying machine with precise dosing system enhances productivity, quality, and safety in shotcreting and similar applications. It enables contractors and operators to achieve consistent and reliable results while optimizing resource utilization and minimizing environmental impact.

Enhanced Productivity

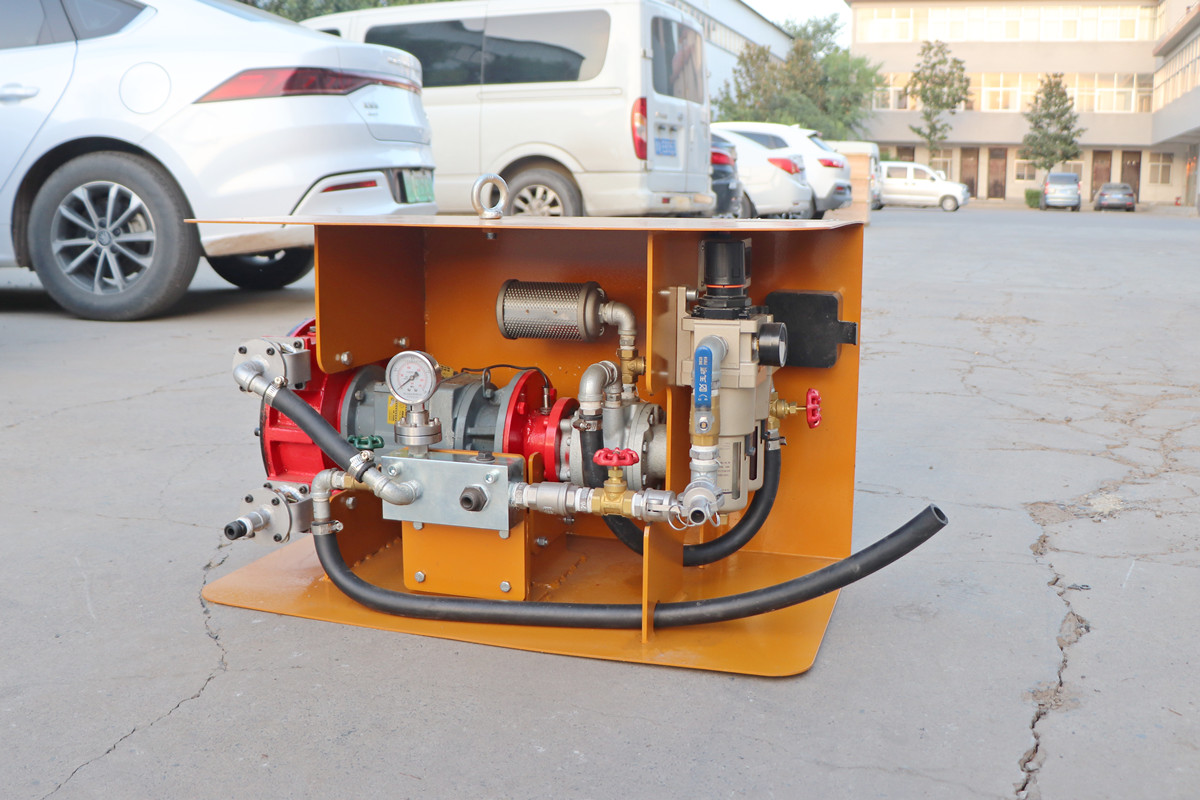

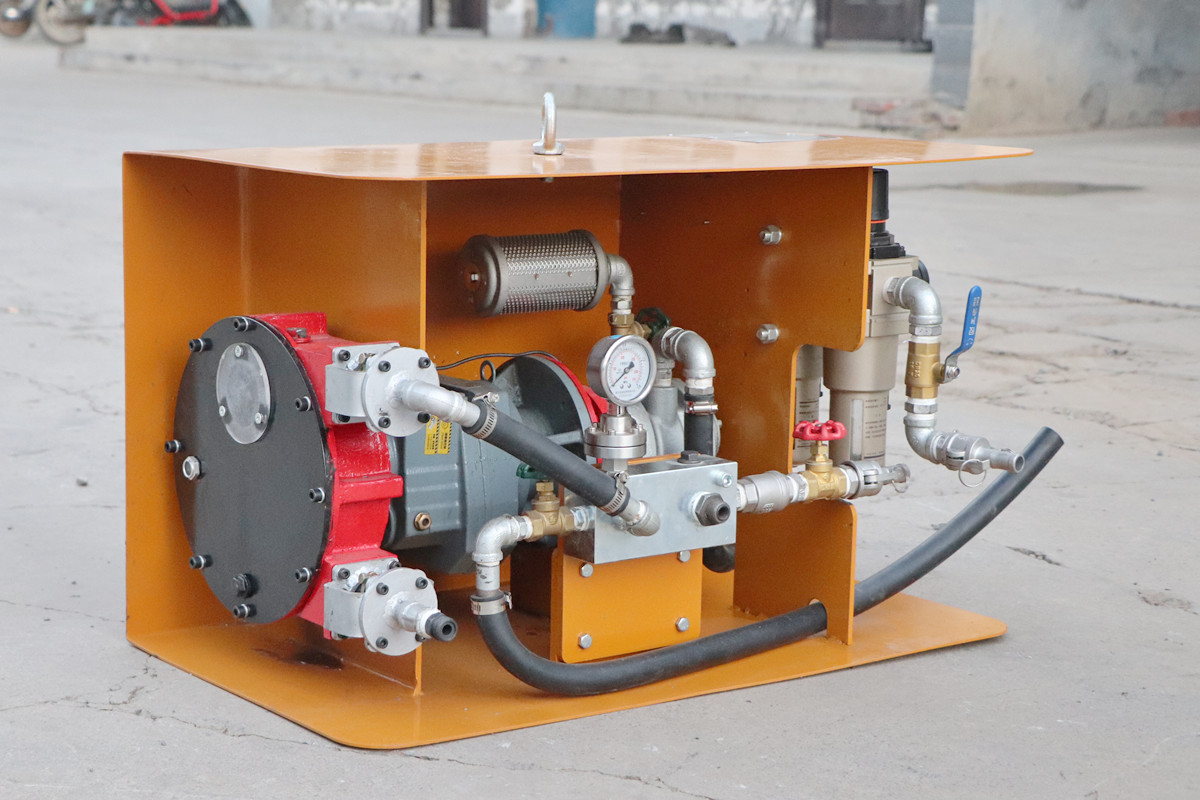

A precise dosing system in a concrete spraying machine allows for consistent and reliable results in shotcreting. This consistency ensures that the required amount of materials, such as cement, aggregates, water, and additives, are accurately mixed and applied. This eliminates the need for repeated applications or corrections, thereby saving time and enhancing overall productivity.

Improved Quality

The precision of the dosing system ensures that the mix proportions are maintained within tight tolerances. This results in higher quality shotcrete with uniform strength, durability, and appearance. High-quality shotcrete is less likely to crack, peel, or fail prematurely, reducing the need for repairs and maintenance.

Increased Safety

A well-designed concrete spraying machine with a precise dosing system minimizes the risk of operator error and over-application of materials. This reduces the potential for hazards such as material spills, slips, and falls, and it also helps to minimize exposure to harmful dust and chemicals. Additionally, precise dosing systems often incorporate automation and controls that further enhance safety by reducing the need for manual handling and adjusting of materials.

Optimized Resource Utilization

By ensuring that only the necessary amount of materials are used, a precise dosing system helps to optimize resource utilization. This reduces waste and the need for additional materials, which can lead to cost savings and a smaller environmental footprint.

Minimized Environmental Impact

The use of a precise dosing system in a concrete spraying machine can help to minimize environmental impact. By reducing waste and overuse of materials, it helps to conserve natural resources and reduce the amount of waste that ends up in landfills or waterways. Additionally, many modern dosing systems incorporate eco-friendly technologies and materials that further reduce the environmental footprint of the shotcreting process.

In summary, a concrete spraying machine with a precise dosing system is a valuable investment for contractors and operators in shotcreting and similar applications. It enhances productivity, improves quality, increases safety, optimizes resource utilization, and minimizes environmental impact. These benefits contribute to a more efficient, sustainable, and profitable operation.