Bentonite compaction cement colloidal backfill grout mixer

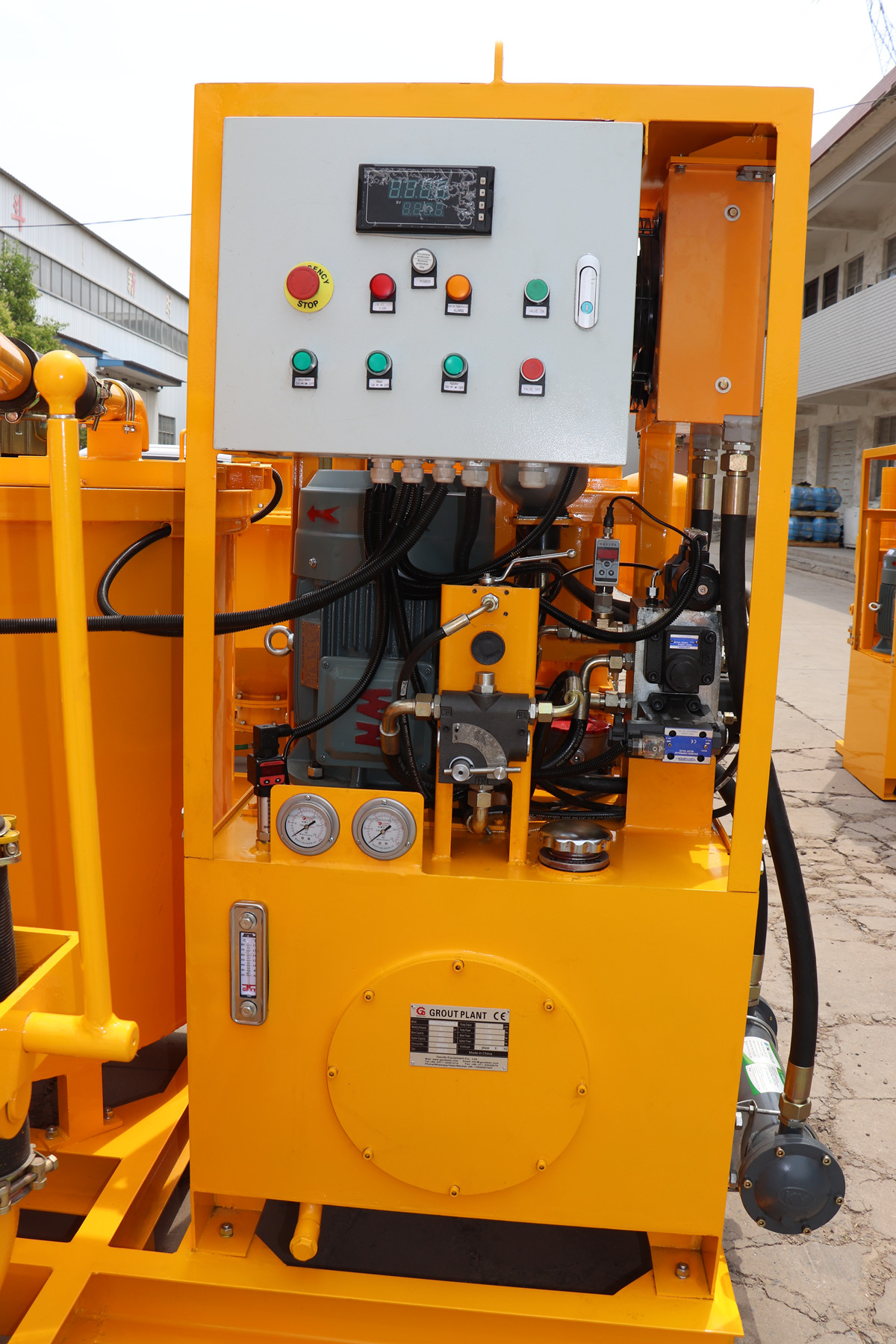

Bentonite compaction cement colloidal backfill grout mixer is a mixing equipment for grout injection in the fields of foundation engineering, soil reinforcement, tunnel construction and excavation. The equipment is mainly composed of mixing tank, conveying system, electric control system, hydraulic system and other parts.

Bentonite compaction cement colloidal backfill grout mixer can mix cement, mortar, bentonite and other materials into a viscous liquid, so that it can form a solid connection between the soil and stone that need to be consolidated. The equipment has the advantages of automatic control, high efficiency and energy saving, convenient movement and easy operation, etc., and can meet the precision and time requirements in construction.

Bentonite compaction cement colloidal backfill grout mixer is a highly efficient and flexible piece of equipment that is designed specifically for mixing cement and water. It is built to fit a standard 20-foot container size, which means that it can be easily transported and stacked with container silos, making it an ideal choice for projects with limited space. Additionally, it features a mobile design that further reduces transportation costs, saving both time and money.

One of the standout features of the bentonite compaction cement colloidal backfill grout mixer is its customizable capacity options. This means that it can be tailored to meet the precise needs of a given project. The plant is also highly automated, with a control system that can regulate the mixing process and ensure high levels of accuracy and consistency. Overall, the auto slurry mixer agitator batching plant is an excellent choice for anyone looking for a reliable and efficient solution for mixing cement and water.