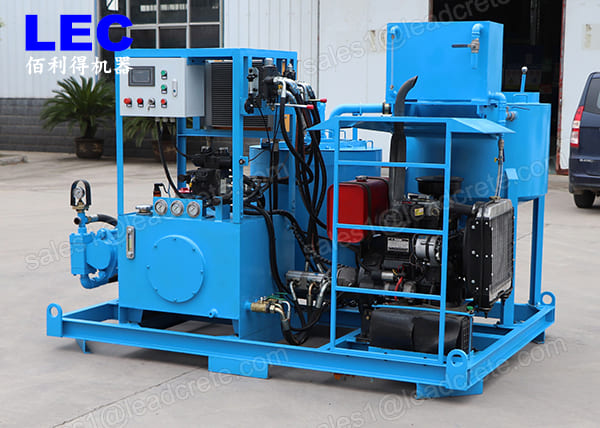

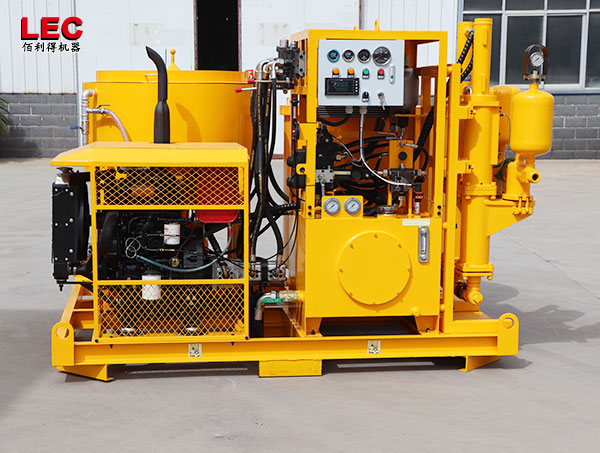

Backfill grout batching plants

Backfill grout batching plants is a combination of agitator, agitator, and grout pump in one piece of equipment. The special mixing effect of cement or bentonite with water is achieved in the mixer by the high turbulence generated in the pump housing. This turbulent flow with high shear forces separates cement or bentonite particles, resulting in a fully hydrated suspension.

As soon as the mixing process is over, the mixture is transferred to the agitator. A slow stirring paddle prevents the grout from settling out of the suspension and removes any air bubbles in the mixture. Each machine is equipped with a mixer and pump with matching capacity, plus a mixing tank that allows for almost continuous operation once work begins.

Any interest you can tell me, so we can give you the best quotation for backfill grout batching plants.

A backfill grout batch plant is a type of industrial equipment used in construction projects to produce backfill grout, which is a material used to fill voids or cavities in soil, rock, or concrete. The batch plant is designed to mix various ingredients such as cement, sand, water, and additives in specific proportions to produce a high-quality backfill grout.

Backfill grout batching plants is a complete set of equipment that combines the pulping machine and the grouting pump to perform high-efficiency and low-consumption work, effectively reducing complex procedures and remote operations. The slurry machine performs high-speed slurry production and storage of cement slurry and similar materials and then pumps the slurry directly to the construction junction to complete continuous slurry grouting.

Backfill grout batching plants are mainly used in the construction of the above-mentioned and underground projects such as roads, railways, hydropower, buildings, mines, etc. Quickly mix media such as water, cement, sand, bentonite, fillers, clays, silicates, and more. Then the plunger grouting pump is used for grouting/grouting to realize waterproof plugging, tunnel lining, foundation, rock reinforcement, filling, etc. This series of grouting pumps have the advantages of a compact structure, high grouting pressure, and a wide application range.

The working principle of the high-pressure backfill grout batching plant is: the high-pressure grouting pump pours a certain proportion of cement slurry into the cement slurry through the grouting pipe; the cement slurry enters the concrete crack under pressure and then fills the concrete to prevent water erosion. Grouting enhances the strength of concrete, and is convenient and quick, with obvious construction effects, and economical and reliable. For example, during the pressed pipe pouring construction process, grouting may fail due to water in the pipe core or failure to reach the preset strength. This type of grouting plant can solve this problem well.