Air motor liquid accelerator dosing system

An air motor liquid accelerator dosing system is a specialized system that utilizes an air motor to drive a pump for metering and dosing liquid accelerator in various industrial applications, such as shotcrete, concrete mixing, and other processes where precise control of chemical additives is crucial.

An air motor liquid accelerator dosing system is a specific type of dosing system used in shotcrete machines or similar applications where precise control of liquid accelerator additives is crucial. Here are the key aspects and functionalities of such a system:

1. **Functionality**: The primary function of an air motor liquid accelerator dosing system is to accurately meter and inject liquid accelerators into the concrete mix during the shotcrete spraying process. Liquid accelerators are additives that promote rapid setting and early strength development of concrete.

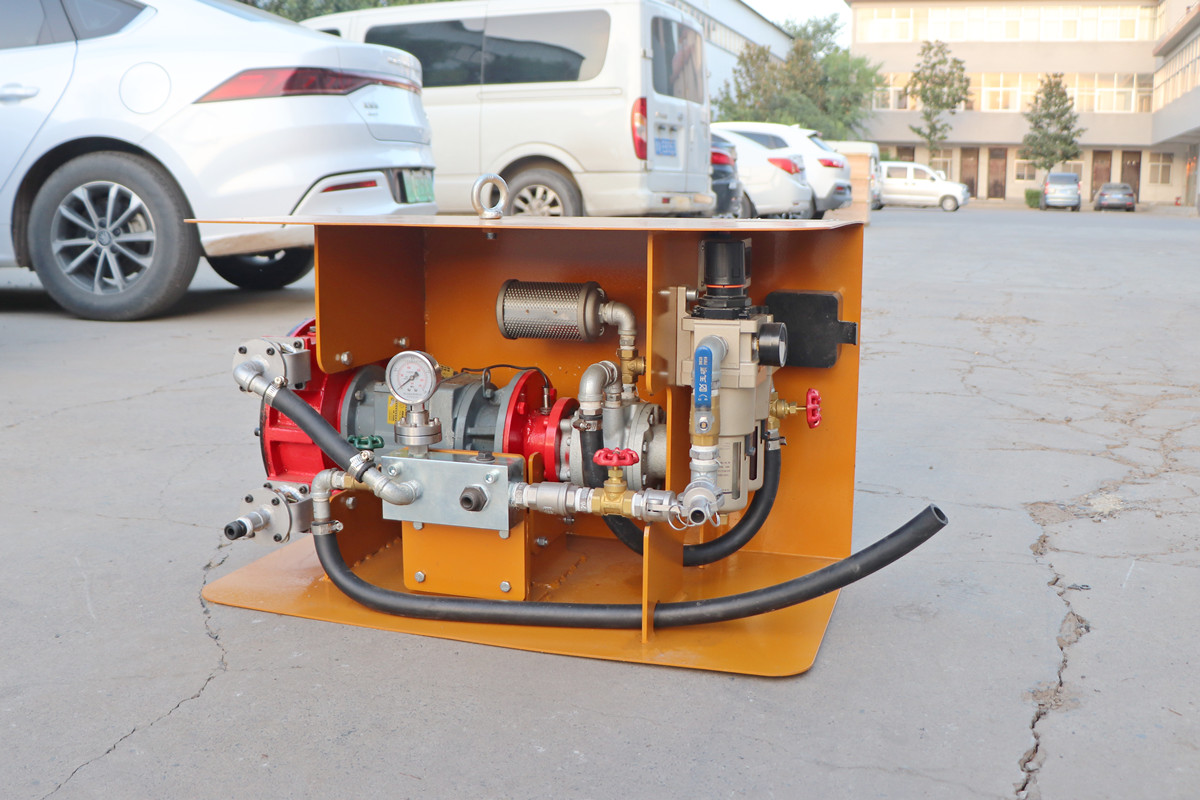

2. **Air Motor**: The system is powered by an air motor, which provides the mechanical force needed to drive the dosing pump or piston. Air motors are chosen for their reliability and suitability for use in potentially hazardous environments such as construction sites.

3. **Dosing Pump or Piston**: This component is responsible for metering the precise amount of liquid accelerator from the storage tank into the concrete mix. It operates based on the air motor’s power, ensuring consistent dosing rates even under varying operational conditions.

4. **Storage Tank**: The liquid accelerator is stored in a dedicated tank that is part of the dosing system. The tank capacity can vary depending on the shotcrete machine’s requirements and the volume of accelerator needed for the project.

5. **Injection System**: Similar to other dosing systems, the injection system includes pipelines, valves, and fittings that transport the liquid accelerator from the storage tank to the mixing chamber or nozzle of the shotcrete machine. The system is designed to handle the abrasive nature of concrete mixtures and withstand the pressures involved in shotcrete spraying.

6. **Control and Monitoring**: Modern systems often include electronic controls that allow operators to monitor and adjust the dosing rate of the liquid accelerator. This ensures precise control over the concrete’s setting time and strength characteristics, tailored to the specific needs of the construction project.

7. **Integration with Shotcrete Equipment**: The air motor liquid accelerator dosing system is integrated into the overall shotcrete machine setup. It works in conjunction with other components such as the concrete mixer, delivery system, and spraying nozzle to ensure efficient and effective application of shotcrete.

8. **Maintenance**: Regular maintenance is essential to keep the dosing system in optimal working condition. This includes cleaning components, replacing worn-out parts, and checking for leaks or blockages in the pipelines.

In summary, an air motor liquid accelerator dosing system plays a crucial role in enhancing the efficiency and quality of shotcrete applications by ensuring accurate and reliable dosing of liquid accelerators. This system helps achieve rapid curing and early strength development of concrete, which is essential in construction projects requiring quick turnaround times or structural repairs.